Prechecks

Tools Required

- Screwdriver (PH1 and PH2 Bits needed)

- Soldering Iron and Wire

- Flush Cutter

Printing The Parts

A variety of 3D printers can be used to print the necessary parts for the arm. Follow these steps for optimal printing results.

1. Select A Printer

When choosing a printer, keep the following recommended specifications in mind. While other printers may work, these specifications are a good starting point:

- Layer Height: Minimum 0.2mm

- Material: PLA+, ABS, PETG, or other durable plastics

- Nozzle Diameter: Maximum 0.4mm

- Infill Density: Approximately 30%

- Suggested Printers: Prusa Mini+, Bambu P1, Ender3, and similar models

2. Prepare The Printer

-

Materials Needed:

- Standard Glue Stick

- Putty Knife

-

Setup and Printing Process:

- Calibrate the printer and level the print bed following your printer’s specific instructions.

- Clean the print bed, removing any dust or grease. If you use water or other cleaning agents, ensure the bed is fully dry.

- Apply a thin, even layer of glue to the print area. Avoid uneven application or clumps.

- Load the printer filament according to the printer's guidelines.

- Adjust the printer settings to match the recommended specifications listed above.

- Verify the file format, select files from the hardware folder, and begin printing.

3. Print The Parts

Print one of each part found in /CAD/STL/common/ and /CAD/STL/leader/. The files are organized as follows:

Leader Parts

- base

- servo_driver_mount

- shoulder_pan

- shoulder_pan_retainer

- shoulder_pan_pin

- shoulder_lift

- elbow

- wrist_1

- as5600_servo_1

- as5600_servo_2

- leader_clamp_base

- leader_wrist_2

- leader_handle

- leader_gripper_finger

Note on Joint 5 & 6:

Joints 5 and 6 use the “AS5600_Servo_2” variant. This variant has a different design and no idle shaft.

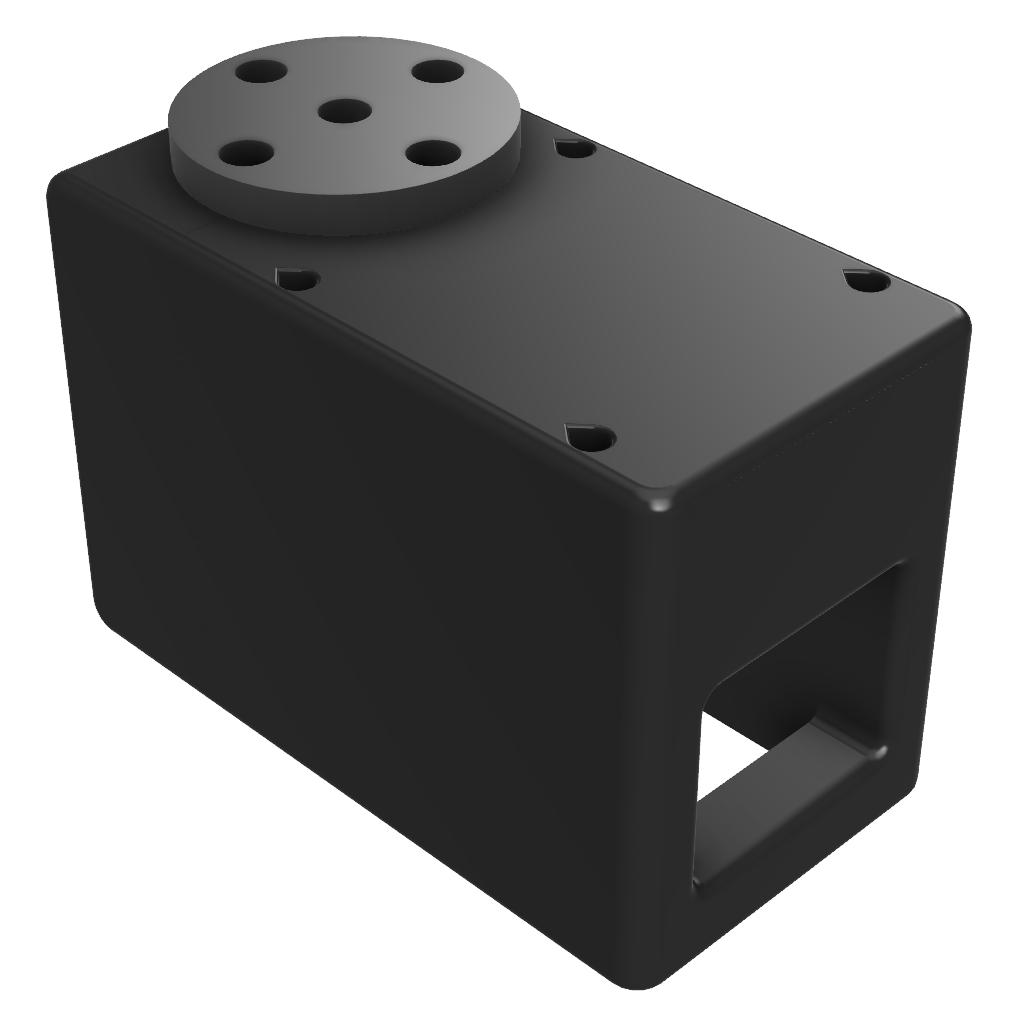

Servo 1

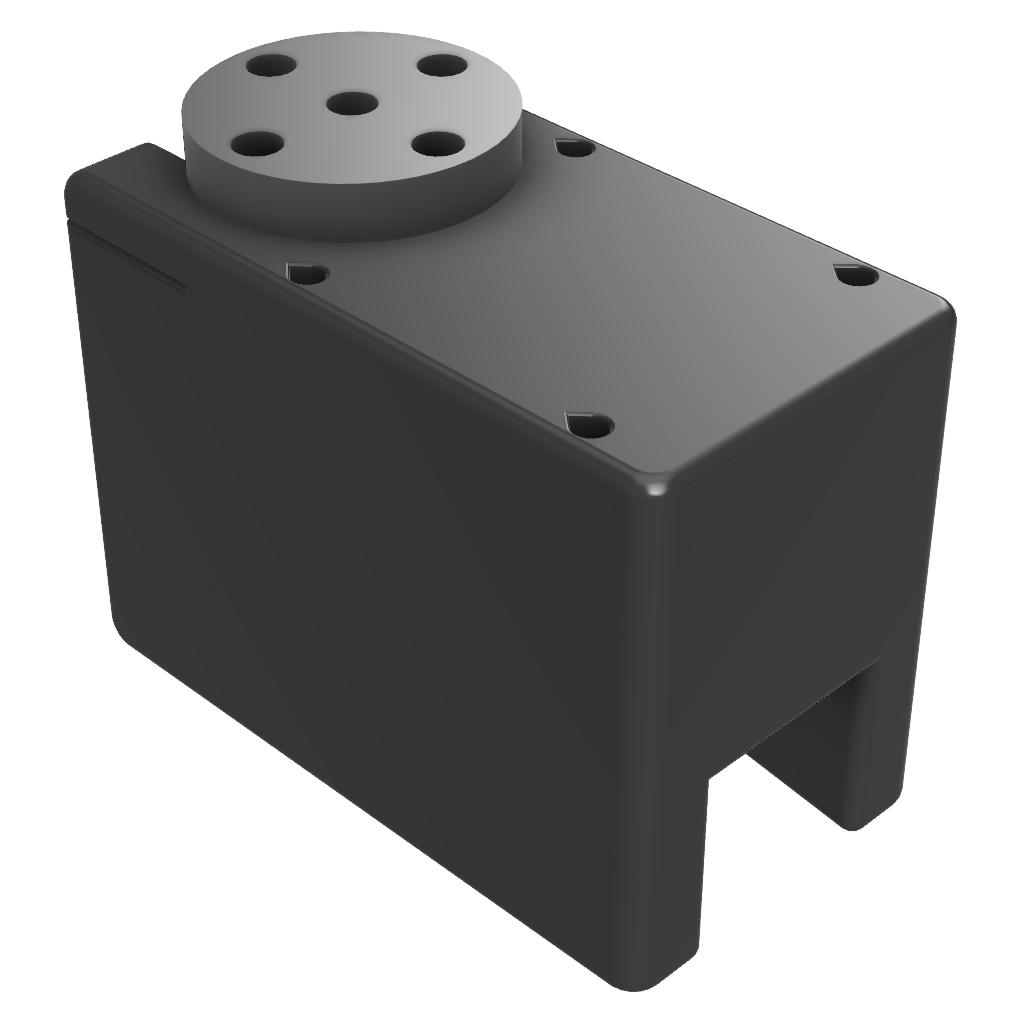

Servo 2